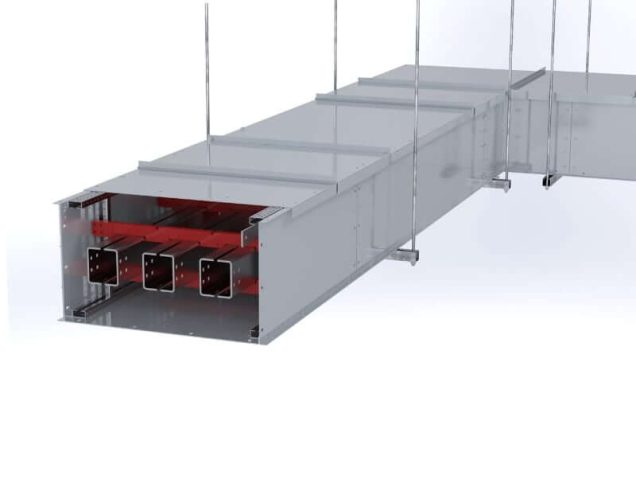

A key part of electrical power distribution is bus duct. Also called bus way, bus duct provides an alternative means of conducting electricity. Bus duct is used in commercial and industrial settings to conduct electricity to power cables or cable bus. Structurally, a bus duct is a sheet metal duct containing either aluminum or copper bus bars (metallic strips or bars that conduct a substantial electrical current) in a grounded metal enclosure.

Bus duct can be installed in most applications where cable or conduit would normally be used. Many people believe bus duct only serves high-amperage applications. This is a misconception–bus way can provide a high degree of efficiency for both low- and high-amperage situations. Bus duct systems are manufactured ranging from 100A to 6500A.

Types of Bus Duct

- A segregated phase bus duct is a metal enclosed bus duct wherein all the three phase bus bars are enclosed in a common enclosure and the all the phases are segregated by means of non-magnetic metal barriers preferably made of the same materials as that of the bus enclosure with degree of protection.

These Segregated phase bus ducts are commonly used in Medium voltage applications with rated voltages from 3.3KV to 33KV and with rated continuous currents up to 5000 Amps with short circuit fault currents of 50 KA for 1 or 3 seconds.

Widely used as an interconnection between transformer to Switchgears, Switchgear to switchgears and also sometimes used as link between small capacity generators and main Transformers under 3 phase, 3 wire configurations.

- Non-segregated bus duct, on the other hand, is almost similar to the above in construction wherein all the phase / Neutral conductors are enclosed in a common enclosure with air as medium of insulation between phases. As the name implies, there is no metallic barriers between phases these bus ducts are relatively compact in comparison with segregated phase bus since the same are generally used for low voltage applications and thus needing much lower electrical clearances between phases and phase to earth.

Widely used as an interconnection between transformer to Switchgears, Switchgear to switchgears and also sometimes used as link between low voltage diesel generators and transformers under 3 phase, 3 wire / 4 wire configurations.

Advantages of using Bus Duct to Cables

- Design: Bus duct have a compact design through which compressed flat conductors can pass through the enclosure.

- Heat Absorption: Since the design is compact and has a metal casing with well-defined surface, bus duct can absorb heat generated while transmissions and distribution of electricity in the walls of the enclosure.

- Flexibility: Bus duct are more flexible in nature compared to cables in the sense that it can be used in any kind of structure with any configuration.

- Cost Savings: Bus duct can be mounted easily than a cable and incurs a lesser cost of installation than traditional cables. They can also be mounted at a lesser time than traditional cables.

- Better Resistance: Bus duct have rigid design elements and hence has better resistance than cables, especially in case of short circuits.

- Safe and Secured: Bus duct are fitted with a steel casing and cannot be damaged by rodents as compared to cables.