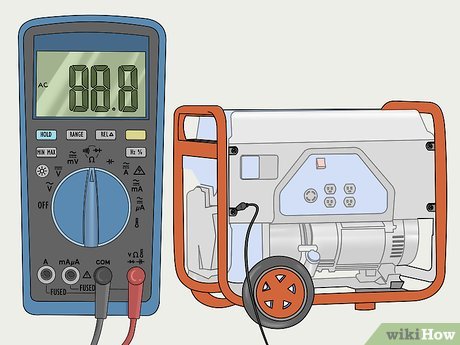

Generator testing assesses the integrity of a generator through the use of computer-supported equipment or tools that monitor trends within the generator. The main objective of generator testing is to reveal hidden problems and prevent unnecessary failure. There are numerous generator testing techniques when it comes to electrical generator testing. Most of these fall under one of two categories: online or offline testing.

Online Mode

Online Dynamic Testing Of Generator

Online dynamic testing is done while the generator is running. It gives technicians data on the power quality and operating condition of the generator. Dynamic testing equipment is able to collect and trend all data essential to the electric generators. Analyzing the collected data from online testing can reveal problems through indicators such as power condition, generator condition and performance, load assessment, and operating efficiency. Power electronically conducts and provides its customers with the following data;

. Partial Discharge Measurement

. Electrical Signature Analysis (ESA)

. Vibration Spectrum Analysis

. Current Spectrum Analysis

. Thermography

Offline Mode

Offline Static Testing Of Generator

Offline static testing should be used on a regular basis to determine how the components within a generator (windings, rotor bar, etc.) are functioning as well as to perform a current and voltage analysis. Static testing finds problems like broken or loose rotor bars, issues with end rings, an unequal air gap between the rotor and stator (eccentricity), and misalignment.

. Visual Inspection Of Stator And Rotor

. Endoscopic Inspection

. EL-CID Test On Stator Core

. Wedge Tapping Test Or Wedge Deflection Test

. Capacitance And Tan Delta Test

. Dielectric Discharge Test

. Partial Discharge Test

. I.R./P.I. Measurement

. HV DC Test

. RTD – Resistance And IR check

. Thermostat Resistance

. Diode Check

. Surge Comparison Test

. Motor Circuit Analysis ( MCA )

. Microscopic / Visual Inspection

. Stator & Rotor Winding Resistance

. Recurrent Surge Oscilloscope ( RSO )

. Rotor Winding Impedance

. Rotor Pole Drop Test

. Exciter/ PMG Tests

An environmental condition such as dirt, dust, and product can build up on windings and lamination vent ducts trapping heat and obstructing ventilation, preventing needed cooling air from reaching the windings and deteriorating the insulation system.

Dry ice cleaning (CO2 cleaning) has become the preferred method for removing these contaminants, on site, from the windings of large generators and motors that are too costly to remove from service for cleaning.

For more information or assistance during normal business hours, call or e-mail TPS at the phone number above. You can also complete and submit our Service Project Inquiry form.